Introduction: The Importance of Choosing the Right Boiler Quality Plates

In industrial boiler manufacturing, the choice of materials directly impacts the safety, efficiency, and longevity of the equipment. Boiler quality (BQ) plates are engineered to withstand extreme temperatures and pressures, making them essential components in boiler construction. Selecting the right BQ plates ensures not only compliance with industry standards but also enhances operational efficiency and durability. DMsons, a leading manufacturer and supplier of boiler quality plates in Mumbai, India, offers expert guidance on choosing the right plates for your industrial needs. This comprehensive guide will help you understand the critical factors to consider when selecting BQ plates.

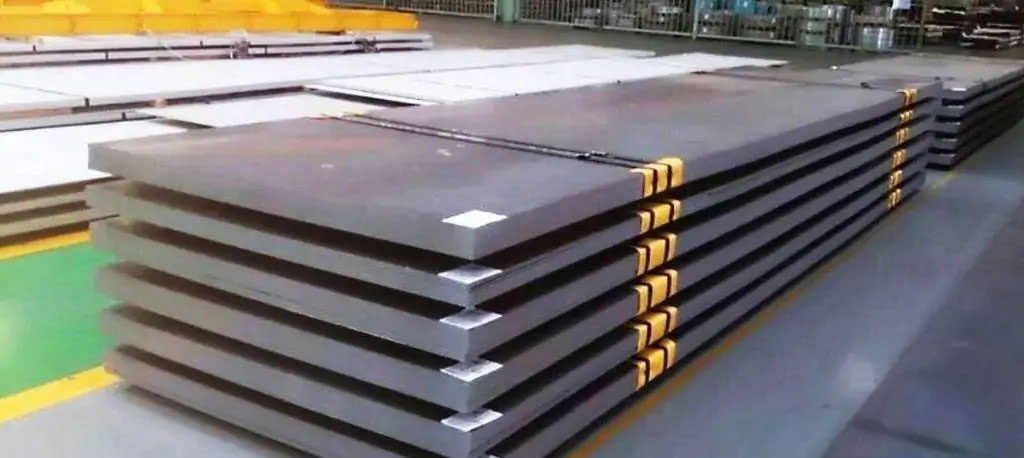

What Are Boiler Quality Plates?

Boiler quality plates are specialized steel plates designed to perform under high-pressure and high-temperature conditions. They are commonly used in the fabrication of boilers, heat exchangers, pressure vessels, and other critical industrial equipment. These plates are manufactured to specific standards to ensure they can handle the rigorous demands of industrial operations.

Key Features of Boiler Quality Plates:

- High Tensile Strength: Ensures resistance to high pressure and mechanical stress.

- Excellent Heat Resistance: Maintains structural integrity at elevated temperatures.

- Superior Corrosion and Oxidation Resistance: Protects against rust and degradation in harsh environments.

- Good Weldability and Formability: Facilitates easy fabrication and installation.

- Durability and Longevity: Reduces maintenance costs and extends service life.

Factors to Consider When Choosing Boiler Quality Plates

Selecting the right BQ plates involves evaluating several critical factors to ensure they meet the specific requirements of your industrial boilers:

- Material Grade and Standards:

- Choose plates that conform to recognized standards such as ASTM A516, IS 2002, and EN 10028. Different grades, like ASTM A516 Gr 60/70, offer varying levels of strength and performance.

- Thickness and Dimensions:

- Consider the required thickness and size based on the boiler’s design specifications. Thicker plates provide greater resistance to pressure but may be heavier and more challenging to fabricate.

- Temperature and Pressure Ratings:

- Ensure the plates can withstand the maximum operating temperatures and pressures of your boiler system.

- Corrosion Resistance:

- For boilers operating in corrosive environments, select plates with enhanced corrosion-resistant properties.

- Weldability and Fabrication Needs:

- Opt for plates that offer good weldability, especially if complex shapes or custom fabrications are required.

- Certification and Compliance:

- Verify that the plates come with proper certifications and meet all regulatory requirements for industrial boilers.

- Supplier Reputation and Quality Assurance:

- Choose a trusted supplier like DMsons to ensure you receive high-quality plates backed by rigorous testing and certification.

Popular Grades of Boiler Quality Plates

- ASTM A516 Gr 60/70:

- Widely used for pressure vessels and boilers, offering excellent strength and corrosion resistance.

- IS 2002 Gr 1/2:

- Indian standard plates known for their durability in high-pressure applications.

- EN 10028 P265GH/P355GH:

- European standard plates with superior high-temperature performance.

- SA 516 Gr 60/70:

- Suitable for moderate and lower-temperature service in pressure vessels.

Applications of Boiler Quality Plates in Industrial Boilers

Boiler quality plates are used in a wide range of industrial applications where high strength and heat resistance are critical:

- Power Plants:

- Used in the construction of steam boilers, heat exchangers, and turbines.

- Oil and Gas Industry:

- Applied in pressure vessels, storage tanks, and offshore drilling equipment.

- Chemical and Petrochemical Plants:

- Utilized in reactors, condensers, and process equipment exposed to high pressure and corrosive materials.

- Shipbuilding:

- Employed in marine boilers and other high-pressure marine equipment.

- Food and Beverage Industry:

- Used in sterilization equipment and high-pressure cooking vessels.

- Pharmaceutical Industry:

- Applied in the fabrication of high-pressure process equipment and reactors.

Specifications of Boiler Quality Plates

| Specification | Details |

| Thickness Range | 6 mm to 150 mm |

| Width | 1500 mm to 3000 mm |

| Length | Up to 12 meters |

| Standards | ASTM A516, IS 2002, EN 10028 |

| Surface Finish | Hot Rolled, Normalized, Quenched |

| Grades Available | ASTM A516 Gr 60/70, IS 2002 Gr 1/2 |

Chemical Composition of Boiler Quality Plates

| Element | ASTM A516 (%) | IS 2002 (%) |

| Carbon | 0.18 – 0.28 | 0.20 – 0.30 |

| Manganese | 0.85 – 1.20 | 0.90 – 1.50 |

| Phosphorus | 0.015 Max | 0.035 Max |

| Sulfur | 0.010 Max | 0.040 Max |

| Silicon | 0.13 – 0.45 | 0.10 – 0.40 |

Mechanical Properties of Boiler Quality Plates

| Property | ASTM A516 | IS 2002 |

| Tensile Strength | 380 – 620 MPa | 410 – 580 MPa |

| Yield Strength | 240 MPa | 250 MPa |

| Elongation | 21% | 22% |

| Impact Energy | 27 J at -20°C | 25 J at -20°C |

Why Choose DMsons for Boiler Quality Plates?

As a leading supplier and manufacturer of boiler quality plates in Mumbai, India, DMsons is dedicated to delivering superior steel solutions that meet the highest industry standards. Our BQ plates are known for their performance, durability, and compliance with global specifications.

- Global Reach: We export boiler quality plates worldwide, ensuring prompt delivery and exceptional service.

- Custom Solutions: Offering tailor-made plates to meet specific industrial requirements.

- Quality Assurance: Rigorous testing and certification to ensure compliance with international standards.

Explore our full range of steel products here: DMsons Steel Products

Factors Influencing the Price of Boiler Quality Plates

The cost of boiler quality plates is influenced by several factors:

- Grade and Specifications: Higher grades and specific requirements can increase costs.

- Plate Thickness and Size: Larger and thicker plates require more material, affecting the price.

- Market Demand: Fluctuations in the global steel market impact pricing.

- Supply Chain and Logistics: Transportation and logistics also play a role in final costs.

For competitive pricing, visit: Boiler Quality Plates Suppliers

FAQs About Boiler Quality Plates for Industrial Boilers

- What are boiler quality plates used for?

Boiler quality plates are used in manufacturing boilers, pressure vessels, power plant equipment, and other high-pressure industrial components. - What is the difference between ASTM A516 Gr 60 and Gr 70?

Gr 70 offers higher tensile strength compared to Gr 60, making it suitable for more demanding applications. - Can boiler quality plates be customized?

Yes, DMsons offers BQ plates in various sizes, thicknesses, and grades to meet specific industrial needs. - Where can I buy boiler quality plates in Mumbai?

You can purchase premium quality boiler quality plates from DMsons, a leading manufacturer and supplier in Mumbai. Contact us here for more details. - Are boiler quality plates cost-effective for industrial projects?

Yes, their durability, low maintenance needs, and long service life make BQ plates a cost-effective solution.

Call-to-Action: Get High-Quality Boiler Quality Plates from DMsons Today!

Looking for premium boiler quality plates for your industrial boilers? DMsons is your trusted partner in Mumbai, India. As a leading manufacturer and supplier, we provide top-grade BQ plates tailored to your specific needs. Visit our Steel Plates Supplier Page or Contact Us today for a quote.

For more industry insights and updates, visit our Blog.