Introduction: Why Alloy Steel Plates Are Vital for High-Pressure Vessel Manufacturing

In industries where high-pressure conditions are common, the materials used must guarantee safety, durability, and performance. Alloy steel plates, with their superior strength and resistance to extreme conditions, are indispensable in high-pressure vessel manufacturing. As a leading manufacturer and supplier of alloy steel plates in Mumbai, India, DMsons delivers high-quality steel solutions tailored to meet the stringent requirements of pressure vessels across industries. This comprehensive guide explores the importance of alloy steel plates in high-pressure vessel manufacturing, detailing their features, benefits, and applications.

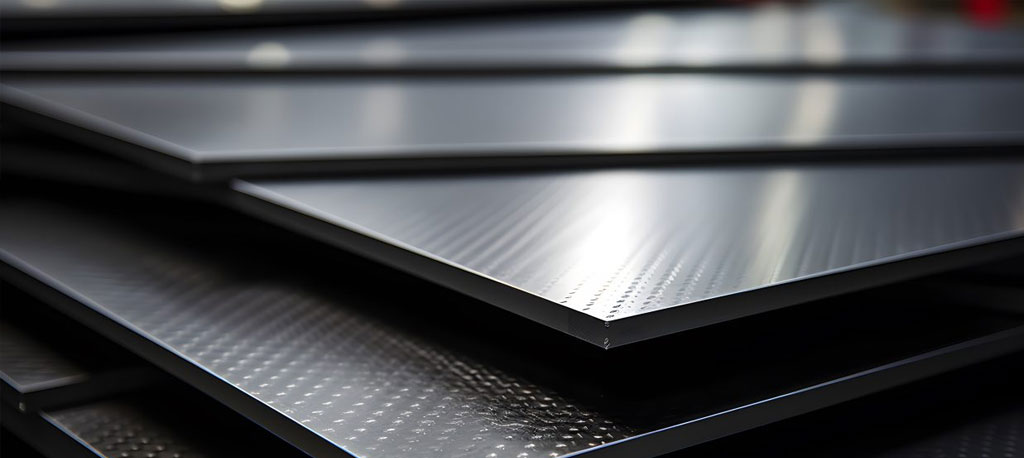

What Are Alloy Steel Plates?

Alloy steel plates are steel sheets that incorporate various alloying elements such as chromium, molybdenum, nickel, and vanadium to enhance mechanical properties like strength, hardness, corrosion resistance, and heat resistance. These plates are specifically engineered for applications that require resistance to high pressure, temperature, and mechanical stress, making them ideal for pressure vessel manufacturing.

Key Features of Alloy Steel Plates:

- High Tensile and Yield Strength: Ensures structural integrity under extreme pressures.

- Superior Heat and Corrosion Resistance: Ideal for high-temperature environments and corrosive substances.

- Excellent Toughness and Hardness: Enhances durability in demanding industrial applications.

- Good Weldability and Machinability: Facilitates easy fabrication while maintaining structural properties.

- Long Service Life: Reduces maintenance costs and enhances operational efficiency.

Applications of Alloy Steel Plates in High-Pressure Vessel Manufacturing

Alloy steel plates are critical in industries where pressure vessels must withstand harsh conditions. Key applications include:

- Oil and Gas Industry:

- Storage Tanks and Pressure Vessels: Used to store and transport gases and liquids under high pressure.

- Drilling Equipment: Provides durability in offshore and onshore drilling operations.

- Petrochemical and Chemical Processing:

- Reactors and Heat Exchangers: Resistant to high temperatures and corrosive chemicals.

- Distillation Columns and Pressure Tanks: Ensures safety and efficiency in chemical processes.

- Power Generation:

- Boilers and Steam Generators: Withstands high pressure and thermal stress in power plants.

- Nuclear Pressure Vessels: Ensures safety in nuclear reactors where extreme conditions prevail.

- Aerospace and Defense:

- Missile and Aircraft Components: Provides strength and resistance to extreme environmental conditions.

- Armored Vehicles and Submarines: Enhances durability in high-pressure and underwater applications.

- Food and Beverage Industry:

- Sterilizers and Pressure Cookers: Used in high-pressure cooking and sterilization equipment.

- Pharmaceutical Industry:

- Autoclaves and Process Vessels: Ensures durability and safety in sterile environments.

Benefits of Using Alloy Steel Plates in Pressure Vessel Manufacturing

- Enhanced Strength and Durability:

- High tensile and yield strength ensures the vessel can withstand extreme pressures without deformation.

- Improved Safety:

- Superior resistance to rupture and fatigue enhances safety in critical industrial applications.

- Corrosion and Heat Resistance:

- Alloying elements like chromium and molybdenum provide excellent resistance to corrosion and high temperatures.

- Cost-Effective Solutions:

- Long service life and reduced maintenance requirements lower operational costs over time.

- Versatile Applications:

- Suitable for diverse industries, from oil and gas to aerospace and power generation.

- Sustainability:

- Fully recyclable, contributing to environmentally friendly manufacturing practices.

Specifications of Alloy Steel Plates

| Specification | Details |

| Thickness Range | 6 mm to 150 mm |

| Width | 1500 mm to 3000 mm |

| Length | Up to 12 meters |

| Standards | ASTM A387, ASME SA387, EN 10028 |

| Grades Available | ASTM A387 Gr 5/9/11/22/91 |

| Surface Finish | Hot Rolled, Normalized, Quenched |

Chemical Composition of Alloy Steel Plates

| Element | Composition (%) |

| Carbon | 0.15 – 0.25 |

| Manganese | 0.50 – 1.50 |

| Chromium | 1.00 – 3.00 |

| Molybdenum | 0.50 – 1.00 |

| Nickel | 0.25 – 1.00 |

| Vanadium | 0.05 – 0.15 |

Mechanical Properties of Alloy Steel Plates

| Property | Value |

| Tensile Strength | 485 – 620 MPa |

| Yield Strength | 275 – 450 MPa |

| Elongation | 20% |

| Impact Energy | 27 J at -20°C |

Why Choose DMsons for Alloy Steel Plates?

As a leading supplier and manufacturer of alloy steel plates in Mumbai, India, DMsons is committed to delivering premium-quality steel solutions for high-pressure vessel manufacturing. Our alloy steel plates are trusted by industries for their strength, durability, and compliance with international standards.

- Global Reach: We export alloy steel plates worldwide, ensuring timely delivery and exceptional customer service.

- Custom Solutions: Offering plates tailored to specific project requirements in terms of size, thickness, and grade.

- Quality Assurance: Rigorous testing and certification ensure compliance with global quality standards.

Explore our full range of steel products here: DMsons Steel Products

Factors Influencing the Price of Alloy Steel Plates

Several factors affect the cost of alloy steel plates:

- Grade and Composition: Higher alloy content and specialized grades increase costs.

- Plate Thickness and Size: Larger and thicker plates require more material, impacting the price.

- Market Demand and Supply: Fluctuations in the global steel market affect pricing.

- Supply Chain and Logistics: Transportation and logistics play a role in the final cost.

For competitive pricing, visit: Alloy Steel Plates Suppliers

FAQs About Alloy Steel Plates in High-Pressure Vessel Manufacturing

- What are alloy steel plates used for in high-pressure vessel manufacturing?

They are used in boilers, storage tanks, reactors, and pressure vessels where high strength and heat resistance are required. - Why are alloy steel plates preferred over carbon steel plates for pressure vessels?

Alloy steel plates offer superior strength, corrosion resistance, and heat resistance compared to carbon steel plates. - Can alloy steel plates be customized?

Yes, DMsons offers alloy steel plates in various sizes, grades, and specifications to meet specific project requirements. - Where can I buy alloy steel plates in Mumbai?

You can purchase high-quality alloy steel plates from DMsons, a leading manufacturer and supplier in Mumbai. Contact us here for more details. - Are alloy steel plates cost-effective for industrial applications?

Yes, their durability and long service life reduce maintenance costs, making them a cost-effective solution.

Call-to-Action: Get High-Quality Alloy Steel Plates from DMsons Today!

Looking for premium alloy steel plates for your high-pressure vessel manufacturing? DMsons is your trusted partner in Mumbai, India. As a leading manufacturer and supplier, we provide top-grade alloy steel plates tailored to your specific requirements. Visit our Steel Plates Supplier Page or Contact Us today for a quote.

For more industry insights and updates, visit our Blog.